Rotary drum thickening Belt dewatering machine

ConsultationProduct overview: It is mainly used for the treatment of sludge without thickening in the thickener (such as the Ao process excess sludge), which depends on the rotary drum concentration and pre dehydration, that is, it has the double functions of concentration and dehydration, and the treatment capacity is higher than single dewatering.

Product features: Combined with foreign design experience, the integrated design of the fuselage makes the whole machine run smoothly without abnormal noise; The surface is coated with top coat, which is beautiful and chemical resistant. The structure is firm and durable; Fully automatic remote and on-site control, effectively reduce manpower, compact model and save civil engineering; It adopts high quality filter cloth and PEX polyester monofilament weaving. High quality brands are used for electric and motor;

Introduction

Introduction

Fully automatic control, high degree of automation, remote and on-site control, effectively reduce the labor force and operation intensity. The machine is compact in structure, beautiful in appearance and small in floor area, which can effectively save the cost of civil engineering. At the same time, it has the characteristics of low energy consumption and low noise. It avoids the defects of high power consumption and high maintenance cost in terms of centrifugal dehydrator and the defects of large structure and complex maintenance of old belt machine. It has low energy consumption, low speed and low noise, and the noise value is ≤ 75db (a). Sludge concentration and dehydration are integrated, automatic cylinder deviation correction system can effectively prevent the deviation of filter cloth, safety alarm device and limit deviation control, and improve the service life and maintenance cost of filter cloth. The wedge-shaped area of sludge dewatering adopts an angle of 6-8 degrees, and the length of the wedge-shaped area is lengthened, so that before the sludge enters the pressing area, the uniformity of the mud cake is effectively controlled, the free water on the sludge surface is further removed, the mud cake is even, and the better effect is obtained in the pressing area. Integrated design, elegant appearance, chemical resistance. The integrated sludge thickening and dewatering machine operates stably and normally without impact, vibration and abnormal sound. All welding passes of the machine are made by TIG welding. The structure is firm, exquisite and durable.

Feature introduction

1.Filter cloth - made of polyester fiber and woven in satin. Long service life, easy to clean, not easy to block, good treatment effect, according to different sludge properties, choose different permeability filter cloth.

2.Wedge pressure zone technology: the angle of wedge zone is reasonable, and the angle between 6 and 8 degrees can improve sludge treatment capacity.

3.Squeezing and dewatering area: adopt the multi-stage squeezing process of initial pressing area, medium pressure area, shear area and high pressure area, so that the sludge is squeezed by gradually increasing pressure, and ensure that the sludge cake has the characteristics of low water content.

4.Compact structure - conditioning tank, sludge concentration device, electric control box, etc. are installed on the main body of the dehydrator. Under the same treatment capacity, the floor area is small, which is about the civil area of the dewatering machine room and the civil engineering cost.

5.The tension and correction system of filter cloth adopts progressive pneumatic flexible tension and serpentine correction technology to ensure the service life of cylinder.

6.Cleaning system - all nozzles of the cleaning system are made of stainless steel, and the machining accuracy is equivalent to the level 6 accuracy of the national standard.

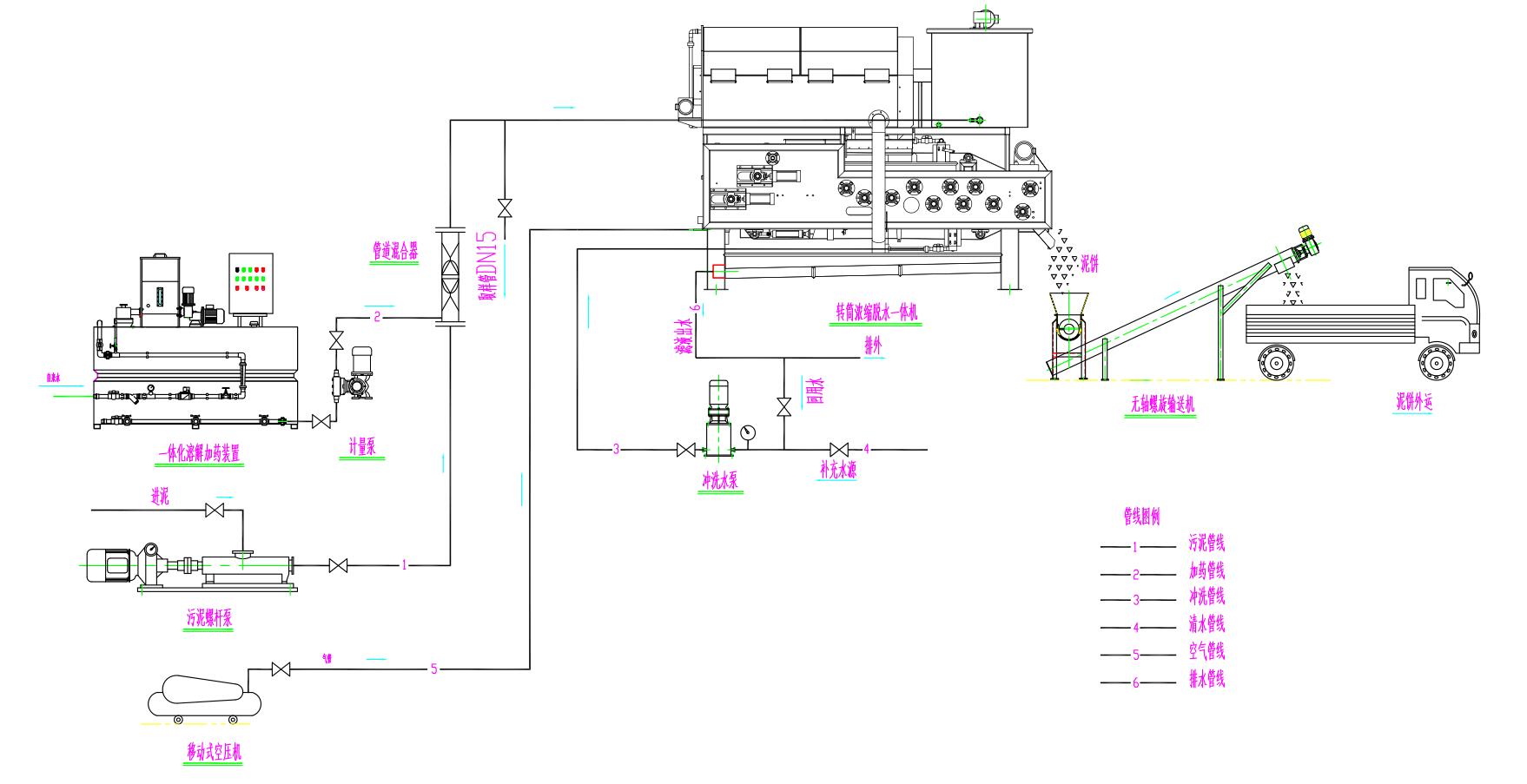

Process flow

| Model | MYZNT1.0 | MYZNT 1.5 | MYZNT 2.0 | Remark | |

| Belt width(mm) | 1000 | 1500 | 2000 | ||

| Flow ( m3/h ) Solids content ( S.S0.8~1.5% ) | 5-10 | 8-15 | 12-20 | By sludge type | |

| Total dry solids ( Kgds/h ) | 75-140 | 110-200 | 180-260 | By sludge type | |

| Outlet water content( % ) | 75-85 | 75-85 | 75-85 | By sludge type | |

| Power (kw) | Drive motor(VFD) | 0.37 | 0.75 | 0.75 | |

| Belt thickener | 0.37 | 0.55 | 0.55 | ||

| Flocculation mixing | 0.37 | 0.55 | 0.75 | ||

| Filtrate | Yes | Yes | No | ||

| Base L1 x W1 ( mm ) | 2100x1300 | 2450x1860 | 2715x2420 | ||

| Weight (KG) | 1100 | 1600 | 2850 | ||

- Last article: no more;

- Next article: Belt Thickening Sludge Dewatering Machine